We invite you to contact us:

Our Customer Service Centre. Monday-Friday: 08:00 – 16:00

[javascript protected email address]

Tel. +48 23 674 30 03

Highest efficiency of machining of wide spectrum of materials such as steels, stainless steels, cast iron, non-ferrous metals and superalloys.

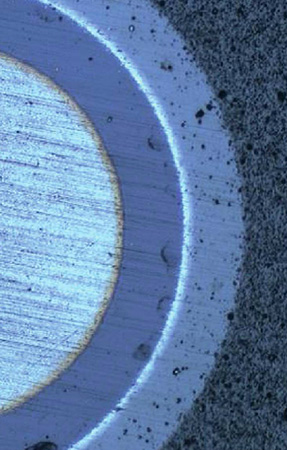

Tools are protected against wear and tear by HL coat. Main components include the TiAIN base, which forms an ideal temperature barrier and top tungsten carbide layer in carbon matrix (WC/C) reducing the build-up, perfect for processing of ductile materials.

Our Customer Service Centre. Monday-Friday: 08:00 – 16:00